If you’re tuning your turbocharged engine, one question comes up more than any other at Penta Performance: should I upgrade to the Turbosmart 7psi wastegate actuator, or stick with my stock 3psi unit?

We get this question almost daily, and for good reason. The actuator is one of those components that can make or break your tuning experience: get it wrong, and you’ll deal with boost spikes, poor drivability, or worse. Get it right, and you’ll unlock your turbo’s full potential.

Let’s dive into the technical details and give you the straight answer on when to upgrade and when to keep things stock.

How Your Wastegate Actuator Actually Works

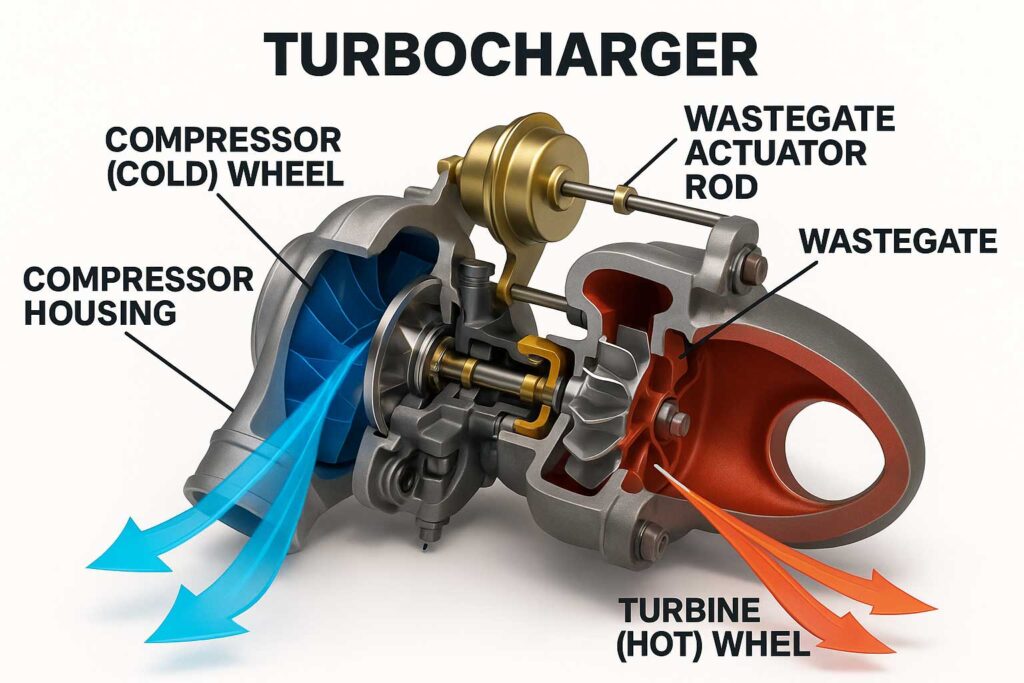

Before we talk upgrades, it’s important to understand what’s happening under your hood. The wastegate actuator is essentially a pressure-controlled valve that regulates your turbocharger’s speed. It works by using boost pressure to push against a spring-loaded diaphragm — when the pressure overcomes the spring force, the wastegate opens, diverting exhaust gas away from the turbine to prevent overboost.

Crack Pressure — When the Wastegate Starts to Open

The crack pressure is the point where the boost pressure is just high enough to begin moving the wastegate actuator rod — the moment the valve “cracks” open. It’s entirely determined by the spring preload inside the actuator.

- A 3 psi spring (stock) means the wastegate starts to open at about 3 psi. The ECU then uses the boost control solenoid (or turbo control valve) to control how quickly and how much boost builds above that point.

- A 7 psi spring (uprated) raises that crack pressure — the wastegate stays shut longer, allowing more exhaust energy to spool the turbo faster, but it also limits how much the ECU can reduce boost.

Base Boost — The Minimum Mechanical Boost Level

When the boost control solenoid is completely bypassed (or unplugged), the turbo operates purely on the actuator spring — no electronic control, no bleed-off. The boost level you get in this state is called base boost, and it’s roughly equal to the spring’s rated crack pressure + a few psi more due to flow dynamics and actuator leverage).

So, if you’re running:

- A 3 psi spring, your base boost will typically be around 5-6 psi.

- A 7 psi spring, your base boost jumps to around 9-10 psi.

Why It Matters

The ECU’s boost control strategy depends heavily on this relationship.

- With a light spring, the ECU has wide authority: it can use the solenoid to build or bleed pressure, easily targeting anywhere between 3base boost psi and the full tuned boost level.

- With a stiffer spring, the ECU loses some flexibility. It can still increase boost, but it can’t lower it below the base boost pressure — the spring physically holds the wastegate shut.

This is why choosing an actuator spring is a tuning decision, not just a hardware upgrade. Too stiff, and your ECU might struggle to control boost smoothly. Too soft, and you may get lazy spool or not tolerant to back pressure.

Exhaust Back Pressure — The Hidden Force Against Your Wastegate

While boost pressure pushes the wastegate open from the actuator side, exhaust back pressure can push it open from the turbine side — often before the actuator spring intends it to.

Back pressure is the exhaust gas pressure that builds up in the turbine housing and exhaust manifold as the turbo works harder. Ideally, the exhaust gases flow smoothly through the turbine wheel and out the downpipe. But on many factory-style turbos — especially the K04 used in numerous OEM performance setups — the turbine side is relatively small and restrictive.

This restriction becomes a problem at higher engine speeds and boost levels. As more exhaust volume tries to pass through the narrow turbine housing, the flow backs up, creating excess pressure upstream of the turbine. It’s not uncommon for a K04 under load to see exhaust manifold pressure exceeding boost pressure by a factor of 1.5–2x at high rpm.

Why That Matters

When back pressure rises that high, it doesn’t just slow flow — it physically pushes on the wastegate valve from inside the turbine housing. If that force exceeds the actuator spring’s closing pressure, it can crack the wastegate open early, even if the ECU isn’t commanding it.

The result:

- Premature wastegate opening

- Boost drop-off in the upper rpm range

- Slower spool recovery between shifts

- Reduced top-end power and efficiency

This is why stiffer actuator springs (like a 7 psi unit) are often used on tuned K04 cars. They don’t “make more boost” by themselves — instead, they resist the internal exhaust pressure that tries to unseat the wastegate under heavy load. The stronger spring helps the turbo hold target boost to redline, where back pressure is at its worst.

The Case for the Uprated 7 psi Spring

✅ Holds Boost at High RPM

At higher engine speeds, exhaust back-pressure increases dramatically. This back-pressure can push your wastegate open prematurely, causing boost to drop off just when you need it most. The stiffer 7 psi spring fights this back-pressure, helping your turbo maintain target boost throughout the rev range.

This is especially critical on tuned setups running significantly more boost than stock. We’ve seen countless logs where cars lose 3-4 psi of boost in the top 1000 rpm.

✅ Reduces Wastegate Duty Cycle

Because the spring itself provides more closing force, your ECU doesn’t need to drive the boost solenoid as hard to maintain boost. Instead of running 90-100% duty cycle trying to keep the wastegate shut, you might see 60-70% duty cycle with the same boost target.

✅ Improves Turbo Spool and Response

More preload on the wastegate flap keeps it tightly sealed during spool-up. This prevents any exhaust gas from bypassing the turbine wheel during those critical early moments when you’re building boost.

The Drawbacks You Need to Consider

⚠️ Higher Minimum Boost

Here’s the big trade-off that many people overlook: A 7 psi spring means your wastegate cannot control boost below approximately 10 psi, regardless of what your ECU commands.

This fundamentally changes how your car drives:

- No more gentle, low-boost operation for part-throttle cruising

- Minimum boost increases across the board

- Drivability becomes more aggressive and “touchy”

- Daily driving comfort can suffer

⚠️ Less ECU Control Authority

The stiffer spring significantly narrows your ECU’s control window. Problems that can emerge include:

- Boost overshoot in lower gears

- Sudden torque spikes in cold weather

- Difficulty maintaining consistent boost under varying conditions

- Reduced ability to run multiple boost maps safely

⚠️ Risk of Overboost and Knock

If your tune isn’t properly adjusted for the new actuator, your car may consistently overshoot boost targets. This pushes:

- Turbo speed higher than intended

- Exhaust gas temperatures beyond safe limits

- Cylinder pressure and knock risk up significantly

CRITICAL: Never permanently run a 7 psi actuator without having your tune revised accordingly.

When the 7 psi Spring Makes Perfect Sense

You should seriously consider upgrading when:

Your logs show maxed duty cycles: If you’re seeing 95-100% wastegate duty cycle and still losing boost at high rpm, the stock actuator is physically unable to keep up with your power goals.

You’re running serious boost: Anything significantly above stock boost levels (generally 18+ psi on most platforms) often requires the extra spring force to maintain control.

You have a custom tune ready: Your tuner understands the change and is prepared to recalibrate wastegate duty tables, boost targets, and safety parameters.

You prioritize peak power over drivability: Track cars, drag cars, and dedicated performance builds where daily driving comfort isn’t the priority.

In short: you need the extra closing force because your turbo system is being pushed harder than the stock spring can handle.

When to Keep Your Stock 3 psi Spring

Stick with stock when:

Your tune is mild to moderate: If you’re running near-stock or modest boost increases, the factory actuator has plenty of authority to maintain control.

Drivability matters: Daily drivers, street cars, and anything that needs to behave predictably in traffic benefits from the ECU’s full control authority.

Your logs look healthy: If your ECU is comfortably maintaining target boost (40-70% duty cycle) without under-boost at high rpm, don’t fix what isn’t broken.

You run multiple boost maps: Low boost maps for economy, high boost for performance: this flexibility requires the wide control range only a stock actuator provides.

For most lightly tuned setups, the stock actuator remains the superior choice because it gives your ECU complete authority to control boost across all driving conditions.

The Correct Approach

Ensure your boost control system is perfect: Before upgrading the actuator, verify your turbo control solenoid, vacuum lines, and boost reference lines are in top condition. Many “actuator problems” are actually boost leak or solenoid issues.

Work with an experienced tuner: Have your wastegate duty tables properly calibrated for the new setup, with appropriate safety margins built in.

Bottom Line: When to Upgrade

The decision comes down to this simple rule: upgrade only if your logs prove the stock actuator can’t handle your power goals.

If your tuner says “we’re maxing out duty cycle and still losing boost at high rpm,” it’s time for the 7 psi spring. If your boost control looks healthy and consistent, stick with stock and keep your ECU in full control.

Remember, the stock actuator isn’t a limitation: it’s a feature that provides maximum flexibility and safety. Don’t upgrade just because you can; upgrade because you need to.

At Penta Performance, we always recommend addressing the actual bottleneck rather than making changes for the sake of modification. Your wallet, your engine, and your daily driving experience will thank you for making the right choice based on data, not assumptions.